How to set a folded saw back. (Video links soon to come, until then see my tab on building a saw for a picture and text version)

How to ship a hand saw.

I have followed the advice of a couple others on the internet and I haven’t been disappointed. I’ve shipped more saws than I can remember and only one arrived with a broken handle, and that was because something to had to of fallen on the flat of the box itself. My biggest concern when shipping is protecting the horns and to keep the saw from getting bent.

First, I like to sandwich the saw in cardboard. Keep it all square and even so that it can then go in another box afterwards without moving around. I score and fold the cardboard so I can make a sheath. VERY IMPORTANT. Make it a little over sized so that you can PINCH the ends down. This gives a corner crash zone area for the saw handle.

I rarely find full pieces of cardboard without flaps in the middle. This of course gives a bend/weak area. I fold another piece of cardboard over these to strengthen the sheath. I sometimes add tape in the flaps to help pinch the saw in place.

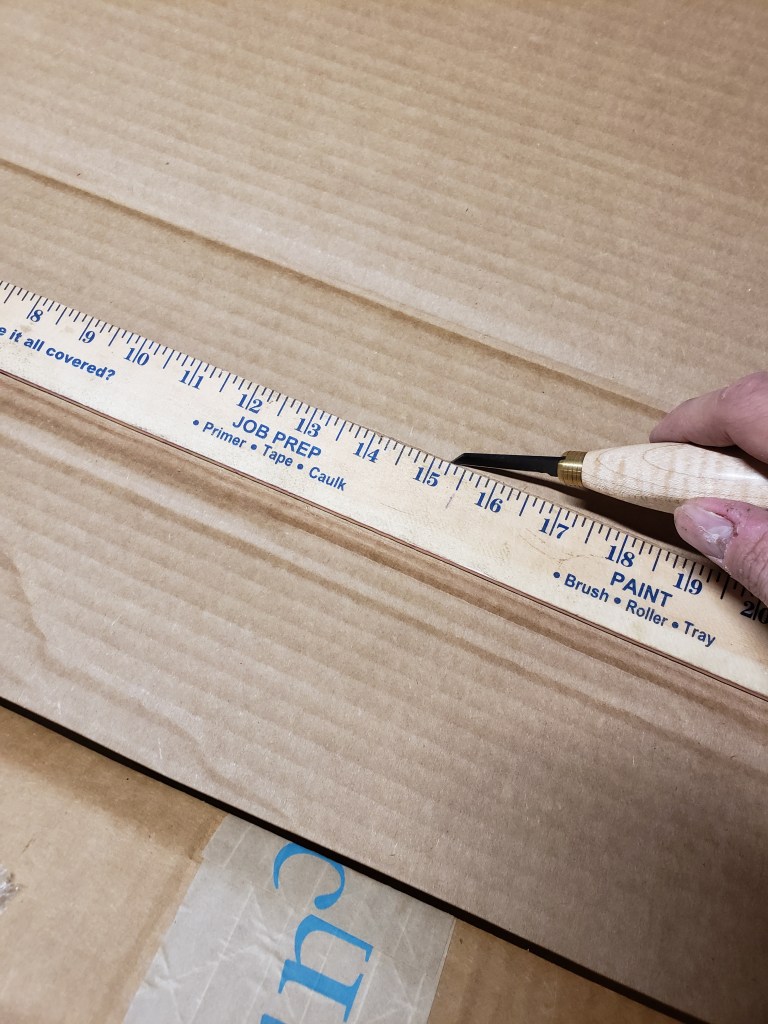

I’ve had some people send me saws just like this. But I prefer to put this inside a nice square cornered box just big enough to keep the sheath from moving around. I have personally found a yard stick to be almost the right width for marking my folds. I score the cardboard to make it easier to fold and build the box around my wrapped saw. I try to find cardboard that is big enough for this part.

I trim all the excess off and if there is any overlap, I leave it and tape it up. Overlapping cardboard just means more cushion! Once done its a nice square stiff box with a sheathed saw inside sandwiched in a way that if dropped off a delivery truck, it would need to crush your square box, crush the pinched over cardboard and then still have enough force to break your horns.