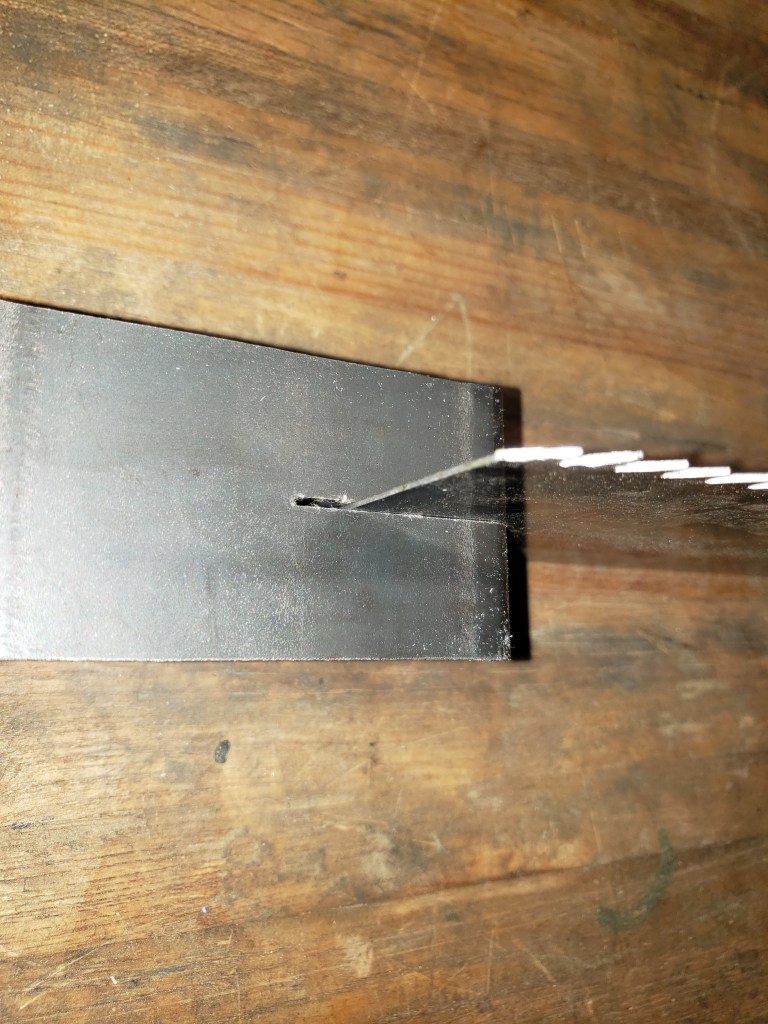

A lot of boxes have been shipped this week. Saw kits, restored saws, kerfing saw plates, and frame saw plates WITH kits. Once I get a little feedback from my “testers / guinea pigs” lol, all volunteers, I will start selling frame saw plates with kits weekly. I’m still working on some little things to help the little stuff get more streamlined, but I’m very happy how they all turned out.

New saws to come will be full size saws. Up until now I’ve only made backsaws and I restored/repaired full size saws. But its been on my to-do list for a bit to make some and a few days ago I was approached with making panel saws. I will keep everyone posted on those.